Feature and Uses

Z4 series DC motors, the prime mover of machinery, are widely used in mill auxiliary of metallurgical industry, metal-cutting machine tool, paper making, printing, textile, printing and dyeing, cement-making as well as plastic extruding machine, etc.

Outline and mounting dimensions of the motors comply with IEC72 Standard, except for the axial distance between the mounting holes (dimension B).

Performance and technical requirements of the motors meet IEC34-1 and DIN57530.

The angular shape of the machine makes good use of space. The use of laminated yokes is suitable for rectifier power supplies, and it can endure both pulsating current and rapid change of current (load change). Pole installation with precise positioning leads to good commutation.

Motors of insulation level F, with reliable insulating construction and impregnating process, ensure stable insulating property and excellent heat dissipation.

The motors possess the features of small size, good performance, light weight, large output, high efficiency and reliability, having achieved the current international advanced level.

Motors can lastingly work under three-phase bridge rectifier and no external smoothing reactor. Motors rated at 160V are powered by single-phase bridge power supply. In that case, a smoothing reactor should be connected to the armature circuit to suppress pulsating current. The inductance is specified in the relevant technical data.

Electrical performance

1. Data listed in the technical data sheet should be employed under the following conditions:

a. Altitude maximum is 1,000m.

b. Cooling air temperature maximum is 40℃.

c. Ambient conditions for motors should be free from acidic, alkaline or other aggressive gases which corrode insulation.

d. Duty: Continuous (S1)

e. Armature and field circuits for motors can be either operated on static eliminator supply or from DC generator.

f. Performances of motors comply with GB631-fundamental technical rules for DC motors.

2. Standard rated voltage: 160V or 440V. 220V, 400V or 660V or other voltage can be derived on request.

3. Rated speed: 3000, 1500, 1000, 750, 600, 500, 400,300 and 200 r/min, totally nine grades.

Decrease armature voltage to make speed regulating under constant torque and lower down field voltage to make speed regulating at constant output.

4. Separate excitation is the basic excitation type of the motors. Nominal field voltage: 180V, other excitation voltages are also acceptable on request.

Forced excitation is allowed with the voltage of less than voltage of less than 500V. When a motor is normally running, its excitation current must not be higher than the rated excitation current.

To assure the reliability of insulation of excitation system, the motor must be protected against self-induction voltages by a release resistor connected in parallel with the field winding when the excitation circuit of the motor is interrupted. At rated field voltage the value of shunt resistor is about seven times field winding resistance(cold state). While the field voltage is higher than nominal voltage, the value of shunt resistance may be lower than seven times field resistance, otherwise higher than seven times.

5. For frame size Z4-315, Z4-355, Z4-355, Z4-400 and Z4-450, compensating winding are provided. For frame size Z4-250 and Z4-280, the motors are feasible with a compensating winding too.

6. A marked earthing terminal is provided for the motors.

7. The efficiency listed in the data sheet is for rated output, voltage and speed, and includes excitation losses, excluding that of separate ventilating fans.

Construction

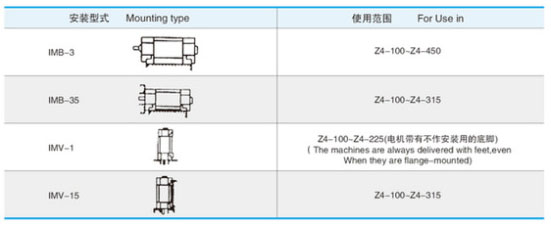

1. Protection, Protection, mounting and type of construction

a. Types of protection of the whole series: IP21S.

b. Mounting modes comply with GB/T997 stipulated as follows:

2. Methods of Cooling

Modes of cooling for all the motors are separate ventilated, force ventilated. The motor is mounted with blower, separately powered ventilating fan, and attached with an air filter. Modes of cooling for motors may be made into three types, namely IC06, IC17 and IC37.

a.For Z4-100~Z4-I60, the blower is mounted on the non-drive side.

b. For Z4-180-Z4-450, the blower is mounted on the drive side.

c. The required cooling air volume, air pressure and fan motor

|

Frame size |

Air Volume

m³/h |

Static pressure

Pa |

Motor Output

KW |

|

Z4-100 |

160 |

200 |

0.04 |

|

Z4-112 |

220 |

300 |

0.06 |

|

Z4-132 |

360 |

450 |

0.18 |

|

Z4-160 |

790 |

600 |

0.37 |

|

Z4-180 |

1200 |

940 |

1.1 |

|

Z4-200 |

1600 |

800 |

1.1 |

|

Z4-225 |

2880 |

1400 |

3.0 |

|

Z4-250 |

3000 |

1400 |

3.0 |

|

Z4-280 |

4000 |

1600 |

4.0 |

|

Z4-315 |

4680 |

1600 |

5.5 |

|

Z4-355 |

5200 |

1600 |

5.5 |

|

Z4-400 |

7200 |

1800 |

5.5 |

|

Z4-450 |

9000 |

1800 |

7.5 |

Motors with the following five methods of cooling can also be ordered, but prior consultations are needed.

a. Frame size 100 up to 250 can be made into the totally enclosed, frame cooled motor(IC 410).

b. Frame size 180 up to 250 can be made into the separately ventilated motor with blower mounted on its non-drive side (1C 05).

c. Frame size 100 up to 200 can be made into the self cooled open motor with its own fan mounted in the shaft (IC 01).

d. Frame size 160 up to 355 can be made into totally enclosed motor with internal cooling air circulation by independent air-air cooler mounted on it (IC 666).

f. Frame size 160 up to 450 can be made into totally enclosed motor with independent air cooler mounted on it (IC 86w).

3. Outlet box mounting is on the right side seen from the drive end of the motor. As an alternative, mounting at the top or on the left side is possible on request.

4. Motors, if needed, can be fitted with tachometer generator or other accessories at the non-drive end.

5. Motors, when directly coupled, must use elastic or flexible couplings. The drive and driven units must be aimed at the utmost care.

Radial forces acting on the shaft-extensions( belt of pinion drive) must not exceed the values given in the diagrams in the following pages (see Appendix 2)

Motors are of compact structure, elegant appearance, spacious terminal box, easy wiring, servicing and maintenance.

Remarks

The ratings, output and speed range through field weakening etc. Listed below are merely for reference. For purposes of incessantly adopting up-to-date technology, the data listed in the following table are subject to relevant change.

Notice on Order

1. Please refer to our sample books before ordering. If the types, ratings you need are not covered by our booklet, please contact us. If you have particular needs, please offer us a specific proposal in advance. A contract or production agreement can be made when requirements are fixed by common consent.

2.Please write clearly the type, output, voltage, speed, duty, type of construction, excitation, field voltage, number of shaft-end, location of terminal box, direction of rotation, necessary accessories and spare parts etc.

3. If the humid-tropical type required, please mark "TH" behind the original type number.

Z4 Series DC Motors

Z Series DC Motors

ZBL4 Series Totally enclosed DC Motors

ZKKL Series DC Motors With Air/Air Cooler

ZKSL Series DC Motors With Air/Water Cooler

ZSN4 Series DC Motors For Cement Rotating Kilns

ZZJ-800 Series DC Motors For Mill Auxiliary

Z2 Series DC Motors

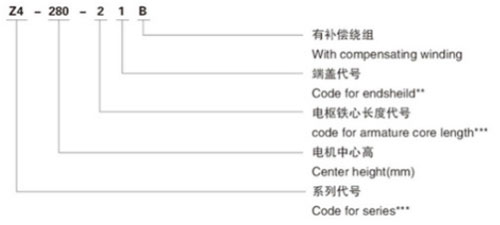

Description (Appendix 1)

Multiple of load implies of armature current(armature circuit characteristic factor).

The figures beside the curves in the drawing are the rated speed of motors.

The multiple of load under speed regulation via field weakening for frame size Z4-160 and below may be consulted with manufacture.

Remarks

During starting a separately excited motor, it needs to turn on the field winding to its rated voltage before switching on the armature circuit. And for stopping, cut off the armature circuit first and then switch off the field circuit, avoiding excessive speed through field weakening when it is starting or stopping.

Z2 Series DC Motors are small and medium-scale DC Motor researched and manufactured by China in 1960s’ with advantages

of reliable performance and best price, which are presently applied extensively into industries such as printing machinery, packing machinery, plastic machinery and so on.

ZZJ-800 series auxiliary transmission DC Motors for rolling mill are products researched and manufactured by China based on the introduced motor manufacturing technology from Mitsubishi Heavy-industry of Japan in 1980s’. Which have international advanced level of earlier of 1990s’. This motor has such features as enduring frequent start, brake, positive rotation and reverse rotation as we as pulsating load when it is used under deteriorating working environment. This motor is mainly used to such position as working roller, depressed device, loop tension, shearing machine, crab crane of iron and steel industry, which is the upgraded product of ZZ/ZZK, ZZY, ZZJV, and ZZJZ series motor. |